Each year, the U.S. energy sector loses close to 3 percent of its natural gas production—worth around $1 billion—to leaks that escape unnoticed into the air. These leaks release methane, a greenhouse gas more than 80 times more powerful than carbon dioxide in the short term. The challenge has long been that methane is invisible to the human eye and difficult to pinpoint across the nation’s vast web of pipes and wells.

A new airborne lidar system, developed by Montana-based Bridger Photonics in partnership with the Massachusetts Institute of Technology’s Lincoln Laboratory, is changing that reality. Using advanced laser amplifiers, the system can map methane plumes from small aircraft or drones with a precision up to 50 times greater than other commercial technologies. Nine of the ten largest U.S. gas producers have already adopted it, and regulators are starting to recognize it as a tool that could transform leak detection and repair strategies across the country.

How the Technology Works

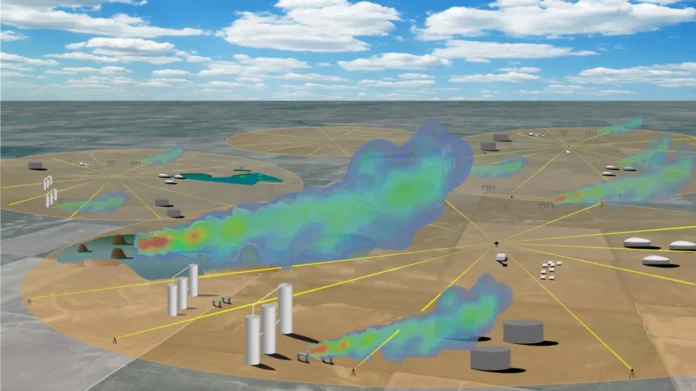

The system relies on a laser operating at a wavelength of 1.65 microns, the exact frequency absorbed by methane molecules. When the laser pulses down from the aircraft, methane plumes reflect the signal differently than normal air. The lidar sensor captures these differences and generates detailed, color-coded maps showing leak locations and volumes.

This process allows operators to see methane leaks as if they were visible smoke. Crews can then prioritize repairs based on leak size and proximity to sensitive areas, cutting both costs and emissions.

The breakthrough came when MIT’s Lincoln Laboratory adapted its slab-coupled optical waveguide amplifier (SCOWA) to boost the laser power needed for long-range detection. Without this amplifier, the system could not have scanned reliably from altitudes of over 1,000 feet.

From Research Funding to Industry Standard

The origins of the project date back to 2014, when the U.S. Advanced Research Projects Agency-Energy (ARPA-E) issued a call for better methane monitoring tools. Bridger Photonics received funding to pursue its idea of pairing topographic mapping with gas detection. But its engineers soon realized they needed a “miracle” laser source powerful enough to detect faint methane signatures from the air.

That “miracle” came in the form of SCOWA technology. With ARPA-E and a Cooperative Research and Development Agreement, Lincoln Laboratory scientists modified their amplifier to work at the methane-sensitive wavelength. The result was a ten-fold boost in power, unlocking commercial viability.

By 2019, Bridger Photonics launched the Gas Mapping Lidar commercially. It immediately won an R&D 100 Award, marking it as one of the year’s most significant innovations in applied science.

Adoption Across the Energy Industry

Today, Bridger’s system is flown over oil and gas fields, pipelines, compressor stations, and distribution networks nationwide. Companies don’t buy the hardware itself; instead, they purchase the data products. The lidar scans identify precise leak locations and quantify emissions, enabling operators to fix problems efficiently.

Chevron, one of the largest U.S. producers, has publicly praised the tool. According to Bruce Niemeyer, president of Chevron’s shale and tight operations, the lidar can identify leaks ten times smaller than those detectable by competitors. This capability, he noted, has shifted leak detection from a reactive exercise to a proactive one.

The Environmental Protection Agency (EPA) gave regulatory approval to the technology in January 2025, signaling that it meets federal standards for methane monitoring. This approval is crucial, as new U.S. methane rules are set to require routine monitoring and prompt repair of leaks across the oil and gas supply chain.

Why Methane Matters

Methane accounts for about 30 percent of global warming since the industrial revolution, according to the United Nations Environment Programme. Cutting methane leaks is one of the fastest and cheapest ways to slow climate change because the gas dissipates from the atmosphere much faster than carbon dioxide.

In the U.S. alone, methane emissions from oil and gas operations represent nearly one-third of total methane releases. Studies have shown that more than half of these emissions come from a small number of “super-emitters,” such as malfunctioning valves, tanks, or compressors. Detecting and repairing these sources quickly can have an outsized impact.

The International Energy Agency estimates that about 40 percent of global methane emissions from oil and gas operations could be eliminated at no net cost, since the captured gas can be sold. Lidar detection makes these savings achievable by showing operators where to focus resources.

Economic and Safety Impacts

For gas producers, keeping methane in the pipe is about more than climate responsibility. Every leak is lost product. For a mid-sized company, undetected leaks can cost tens of millions of dollars annually.

There is also the safety dimension. Methane is flammable, and concentrated leaks can create explosion hazards near populated areas or industrial facilities. Traditional leak detection methods, such as handheld sniffers or ground vehicles, are slow and often miss small but significant leaks.

Airborne lidar covers hundreds of miles of pipeline in a single day, identifying leaks before they escalate. Repair crews no longer waste time patrolling stretches of pipe that are leak-free, reducing labor costs and boosting safety margins.

A Legacy of Laser Innovation

MIT’s Lincoln Laboratory has been at the forefront of laser technology for decades. It was among the first to demonstrate the diode laser in the 1960s, and its researchers later spun out companies that advanced fiber-optic communication and industrial cutting lasers.

The SCOWA amplifier, developed in the early 2000s, was initially designed to strengthen signals in optical communications and defense applications. Its adaptation to methane detection is an example of how government-funded R&D can yield unexpected commercial benefits.

Researchers at Lincoln Laboratory are now exploring how SCOWA devices can be paired with photonic integrated circuits, potentially advancing quantum computing and sensing. This could further expand the technology’s impact beyond energy and climate into fields like secure communications and national defense.

The Regulatory Push

The Biden administration has pledged to cut U.S. methane emissions from the oil and gas sector by 75 percent by 2030. New rules finalized in 2023 require companies to monitor large well sites quarterly and small sites annually.

Before lidar, meeting these rules would have been costly and logistically complex. Ground crews using conventional tools would need years to cover the network. With airborne lidar, regulators can confirm compliance more efficiently, and companies can avoid penalties by repairing leaks quickly.

Internationally, the U.S. joined the Global Methane Pledge, an agreement by more than 150 countries to reduce methane emissions 30 percent by 2030. Technologies like Bridger’s lidar make such targets realistic.

Looking Ahead

As demand for methane detection grows, Bridger Photonics is scaling up operations. The company is expanding partnerships with airlines that mount the lidar on survey planes, and it is testing drone-mounted versions for hard-to-reach facilities.

The next step may be integrating real-time leak alerts directly into operators’ control rooms, enabling immediate response. Researchers are also exploring machine-learning algorithms that can analyze lidar data to predict where future leaks are most likely to occur, based on infrastructure age, environmental conditions, and maintenance history.

Meanwhile, Lincoln Laboratory continues to refine optical amplifiers and explore broader applications of SCOWA. Its new Compound Semiconductor Laboratory – Microsystem Integration Facility, set to open soon, will provide advanced prototyping capabilities for future laser systems.

The Bottom Line

Methane detection may not grab headlines like solar farms or electric vehicles, but its impact could be just as large. A single leak detection flight can prevent thousands of tons of greenhouse gas from reaching the atmosphere, while saving companies millions in lost product.

With airborne lidar now in wide commercial use, the gas industry has a proven tool to align economic and environmental goals. The combination of university research, government funding, and private innovation has delivered a solution that seemed impossible just a decade ago.

In the race to cut emissions, keep communities safe, and secure energy supplies, keeping methane in the pipe is more than a slogan—it is an achievable reality backed by cutting-edge science.